Why Cold-Rolled Steel Is Essential for High-Strength Components

Steel is an incredibly strong material which is used to make things such as cars, buildings and machines. Its strength is higher and it’s more durable than regular steel. In this lesson, we’ll look a little more in depth at why cold-rolled steel is such a key ingredient for fabricating things that need to be extra strong.

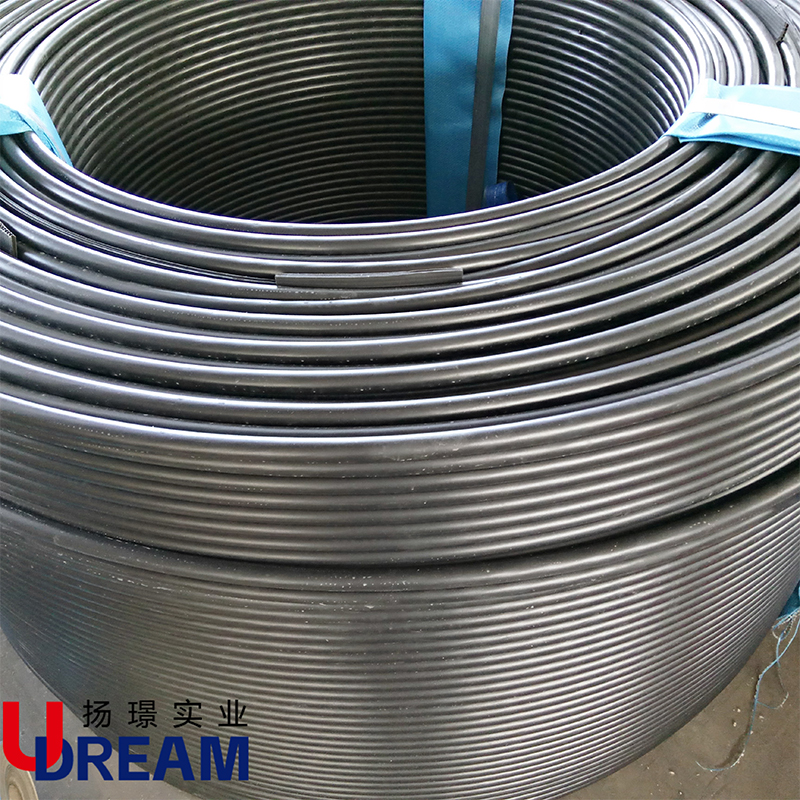

The Process of Making Cold-Rolled Steel:

Cold-rolled steel is produced by squeezing regular steel through rollers when it’s cold. This treatment makes the steel harder and stronger. Cold-rolled steel can take a whole lot of punishment without breaking, so it’s great for producing strong objects that need to last a very long time.

The Advantages of Cold-Rolled Steel:

Things made with cold-rolled steel are better and last longer.” Parts made of cold-rolled steel can hold heavy weights, resist temperatures that can be extremely hot or cold, and withstand the tests of tough conditions without bending or cracking.” This makes machines, tools, and buildings of cold-rolled steel strong and durable, and they can handle all kinds of wear for a long time.

Creating powerful parts from cold-rolled steel:

Parts that are strong have to be made carefully and uniformly, so they are safe and reliable. Cold-rolled steel is well suited to this because it is easy 1 1 2 galvanized pipe to form very accurately. What this means is that components constructed from cold-rolled steel fit together precisely and also work well together, and this matters when it comes to how effectively the end product functions.

The Strength Control of Steel:

The cold-rolling technique enables manufacturers to determine how strong the steel will be. And by altering the temperature, pressure and speed of the rollers, they can produce cold-rolled steel in the strength, hardness and flexibility specifications that they desire. This is ideal for cold-rolled steel, because cold rolling is a way of shaping 1 4 inch stainless steel tubing steel at room temperature to get the best results, possible with a metal that doesn’t need to be at a high temperature throughout the process.

Why We Need Cold-Rolled Steel for Progress:

It is significant for cold-rolled steel for it new thoughts and development that applications. It enables engineers and designers to design better products. With cold-rolled steel, makers can make lighter, stronger, more efficient parts that improve upon technology, transportation, construction and many other aspects of modern life, benefiting us all.

In the end, cold-rolled steel is one of the most important materials you can use to create parts that are very strong and tough. Through the use of cold-rolled steel, companies can develop better products that are more realistic, resulting in a precise strength that 1 4 stainless steel tubing is instrumental as a material in advancing various industries. UDREAM is proud to be in the forefront of producing such quality cold-rolled steel that will build a better tomorrow for all.

Comments

Post a Comment