Vertical Plastic Molding for Aerospace: Lightweight Composites and Structural Plastic Components

Application of Low-Weight Composites in Vertical Plastic Forming for Aviation industry

In the fast-paced world of aerospace engineering, cutting weight off an airplane or a spacecraft is a big deal. It’s these materials when used in the specific function of making vehicles faster and use less fuel. A significant group of materials in this area are light composites. These are strong materials made by combining many things. They are ideal, for instance, for vertical plastic molding, a novel approach to molding plastic into intricate parts for aerospace.

How Plastic Parts for Aerospace Are Made dequeueReusableCell The Technology Behind Making Plastic Parts for Aerospace.

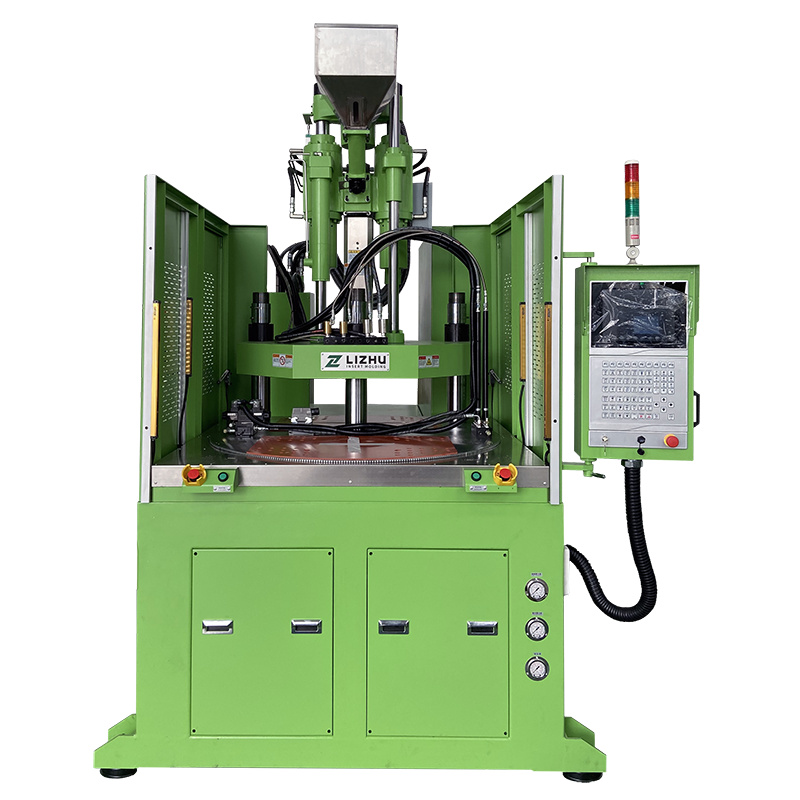

Plastic molding process The vertical Plastic molding is a unique process that a lot of companies take advantage of. It means melting plastic pellets, then injecting the molten plastic into a mould to form the desired shapes. It is a process that engineers use to create lightweight and strong parts that are essential in aerospace. At LIZHU MACHINERY we utilize the latest CNC machines and have engineering capabilities that include excellent CAD designing and we also CMM so that our plastic products used for aerospace are of the highest quality and extremely accurate too.

Advantages of Vertical Plastic Molding for Aerospace Components In the aviation industry, precision matters the most.

There are several semi automatic vertical injection moulding machine advantages of vertical plastic injection molding. One major benefit is that it can be used to make complex shapes and patterns that are difficult to construct with other methods. This process also contributes to making lighter parts that decrease the overall weight of airplanes, enhancing fuel efficiency and performance. At LIZHU MACHINERY, we leverage these advantages to supply high-quality plastic components for customers in the aerospace industry.

Satisfying the Demands of the Aerospace Industry Through Vertical Plastic Molding

The aerospace industry imposes stringent requirements on the materials and parts of aircraft and spacecraft. Those rules would require tough, strong parts that can withstand both high temperatures and pressures. Vertical small vertical injection molding machine plastic molding enables us to attain these high standards by producing durable, lightweight parts that can handle the harsh conditions of space and high-altitude flight. Our staffs here at LIZHU MACHINERY strive to provide equipment with these crucial standards by all of you.

The Way New Techniques, Materials and Designs are Impacting Aerospace Manufacturing

Recently, lots of new ideas were proposed regarding materials and designing methods in aerospace manufacturing. New technologies like light-weight composites and plastic vertical molding have altered the way aircraft and spacecraft are made. This in turn translates into faster, more efficient and more eco-friendly cars. Companies such as LIZHU MACHINERY are the leading manufacturers in the aerospace sector - we offer robust plastic components that help to significantly enhance the performance and reliability of the aerospace vehicle.

In Conclusion

Aerospace manufacturing is a large user of vertical plastic vertical hydraulic injection moulding machine molding. It can be used to make lightweight composites and strong plastic parts necessary for constructing modern airplanes and space craft. With the aid of materials new technology new markets and new end-users companies like LIZHU MACHINERY is driving the future of aerospace designing while raising the bar for innovation beauty and performance.

Comments

Post a Comment