Regulatory Compliance in Vertical Injection Molding: ISO Standards for Medical and Food-Grade Parts

When companies produce things like medical tools and food containers, there are rules that they have to follow to keep those items safe for use. These rules are known as regulations, and they are very important in order to ensure that the things we use every day are safe for us. One way that businesses can adhere to these rules is by utilizing a process known as vertical injection molding. This is why companies must use a special machine to mould molten material into the correct shape by adding it into a form.

Significance of Using ISO Standards to Produce Safe Products

ISO standards are sort of like a manual of rules that companies can use to make sure that the things they make are made safely and of high quality. ISO is the acronym for International Organization for Standardization. These standards help ensure that products are manufactured the same way every time, and meet certain safety criteria. In vertical injection molding, compliance with the International Organization for Standardization is critical to guarantee that medical tools and food containers aren’t laced with chemicals that can make people sick.

Quality and Safety ISO Standards

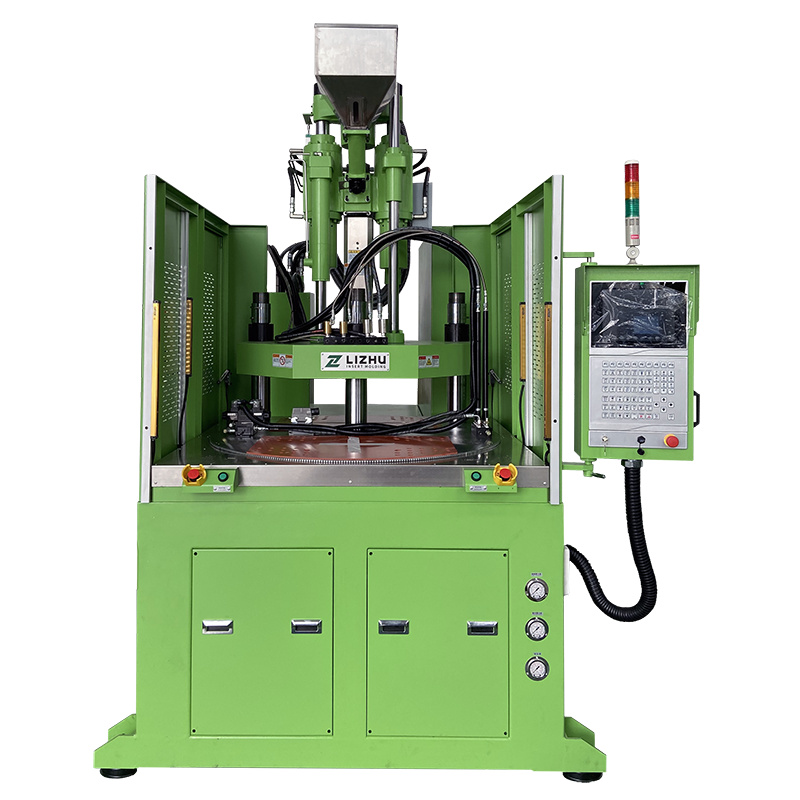

Quality and safety should be the main consideration when making medical tools and food containers. With vertical injection molding, companies can use ISO standards to ensure the products they design and manufacture are safe for consumers to use. That is to say the products are free of errors and dirt and all the rest, things that could injure users. By complying with these guidelines, companies such as LIZHU MACHINERY can ensure that their products adhere to the rules set by more stringent safety agencies.

Struggling with the rules

ISO compliance is important insofar as it pertains to ISO standards, but companies will still face issues when it comes to compliance in product regulations, particularly vertical molding. One problem they face is keeping up with ever-changing regulations, and ensuring their products are in compliance with the latest standards. Businesses must keep abreast of changes in regulations and make their production processes comply with them. If you continue to be kept in the loop and adjust in accordance with new laws, companies can take the right action to ensure compliance.

Best Ways to Follow the Rules

To ensure that vertical insert molding they comply with the rules when producing medical and food-grade parts, companies can adopt some best practices. This includes conducting regular audits of their production process for any problems, monitoring production through strict quality control processes, and training their workers how to safely man the manufacturing lines. Adhering to these best practices will minimize the risk of rule violations and help ensure that your products are high quality and safe.

Marke take away: Rules are rules and in vertical injection molding it vertical insert moulding machine is especially important to keep medical tools and food containers safe and healthy. Adhering to ISO standards and best practices allows companies like LIZHU MACHINERY to face the regulatory challenges and achieve robust products for the stringent demands of safety vertical molding machine price agencies. And this commitment to obeying the rules not only keeps consumers safe, it also legitimizes the products that we rely on every day.

Comments

Post a Comment