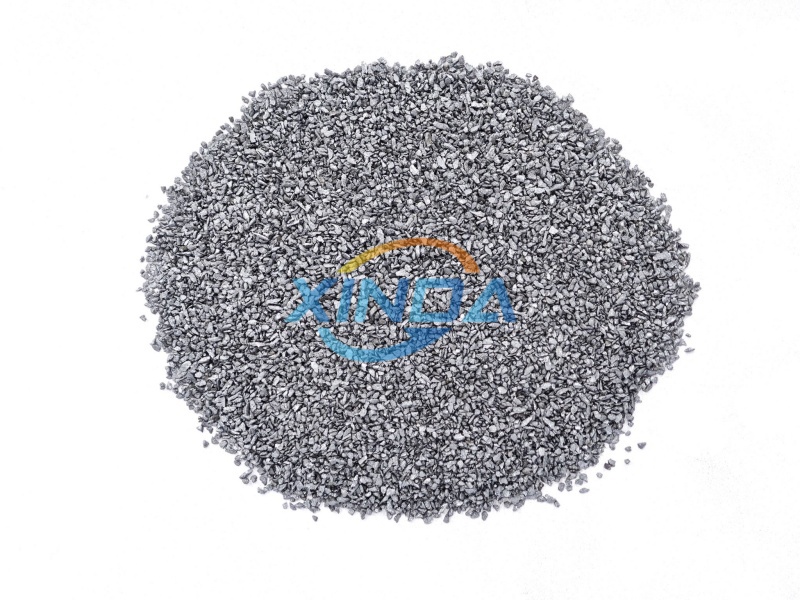

Carbon Composite Silicon Alloy for Furnace Additives

Xinda has developed new material they call their carbon composite silicon alloy additives, which is shaking up the way furnaces operate. These new blends enable furnaces to run more efficiently, heat things up more quickly, reduce maintenance costs and last longer. Let's take a look at how Xinda's additives are changing the game for furnaces.

Making Furnaces Work Better

Xinda’s carbon composite silicon alloy additives are designed to assist the furnaces in working more efficiently. If these supplements have been added to the oven mixtures, operators may see an increase in how well the oven works. So-called additives help the furnace to burn fuel more efficiently, which in turn means more dependable heat. This reduces heat-up time and increases productivity, allowing your furnace to work more efficiently overall.

Improving Heat Transfer

One of the big advantages of Xinda’s additives is that they promote heat transfer in furnaces. These additions render the materials in the furnace more thermally conductive, permitting heat to be conducted faster and more efficiently. This translates to more uniform heating in the furnace, fewer hot spots and better temperature control. With better ht, operators can save energy and decrease costs.

Lowering Maintenance Costs

Carbon fibre-added silicon alloy by Xinda can also reduce the cost of furnace maintenance. Using these additives, operators can observe less wear and tear to the critical components of the furnace. This translates into fewer breakdowns and less time spent on repairs. This can save operators a lot of money over time, further proving that Xinda’s additives are a wise choice.

Making Furnaces Last Longer

Furnaces need silicon barium calcium to be durable and dependable. The company’s additives are specifically designed to extend the life of furnaces. When added to the furnace materials, users can anticipate fewer damages from rusting and wear. That in turn means the furnaces will last longer and need replacing less frequently, saving sialbaca both time and money.

Innovation for Production Processes

Xinda’s carbon composite silicon alloy additives are also one of the most advanced and new technology for furnaces. When they add these to processing, they can see that things are being produced better. These additives provide easier operations, increase productivity, and enhance efficiency. This, in turn, results in a more efficient and profitable operation and will at all times benefit every sialbaca alloy operation of a furnace.

In closing, Xinda’s carbon composite silicon alloy additives will disrupt the furnace game. They contribute to performance enhancement, heat transfer, cost reduction, durability enhancement and production process optimization. With the help of Xinda additives, you can get better efficiency and productivity. Clearly, the Xinda additives are redefining the way furnaces function.

Comments

Post a Comment