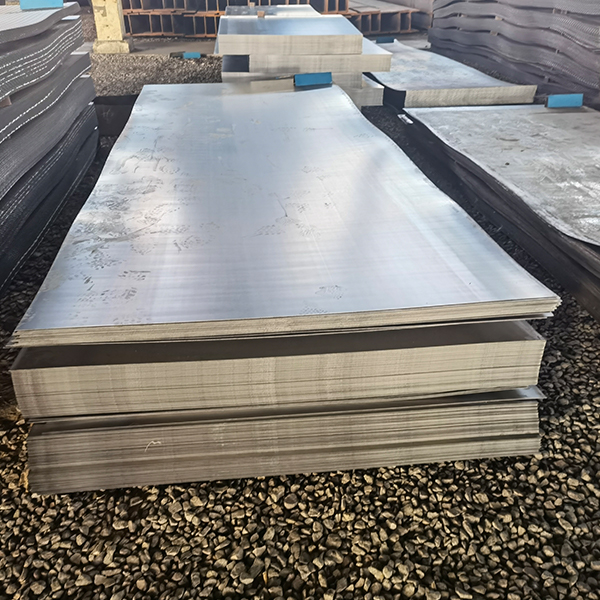

Low Carbon Steel Sheet: Flexible & Weldable for Various Applications

Low Carbon Steel Sheet: Flexible & Weldable for Various Applications

The combination of flexibility and weldability makes low carbon steel sheets indispensable in industries requiring durable yet adaptable materials. These sheets can be seamlessly integrated into diverse applications, from structural frameworks to decorative elements, thanks to their ability to withstand various joining methods and environmental conditions. Their versatility is particularly evident in construction and infrastructure projects, where materials must adapt to dynamic loads and environmental stresses.

In welding galvanized sheet metal applications, low carbon steel sheets demonstrate superior performance compared to higher-carbon alternatives. The reduced carbon content minimizes the risk of cracking in heat-affected zones, allowing for cleaner, stronger welds. This quality is critical for applications like pipeline construction and storage tank fabrication, where weld integrity directly impacts safety and longevity. Some manufacturers employ advanced welding techniques steel channel such as TIG or resistance welding to achieve precis aluminium pipee, high-strength joints without compromising the material’s inherent flexibility. The sheets’ consistent chemical composition ensures uniform weld quality across large production runs, a key factor for industrial projects requiring standardized components.

The flexibility of low carbon steel sheets extends beyond physical bending to encompass functional adaptability. In the renewable energy sector, these sheets form the basis for solar panel mounts and wind turbine components that must endure constant environmental exposure while maintaining structural stability. Their corrosion resistance, when properly coated, allows for outdoor use in harsh climates without significant degradation. Additionally, the material’s electromagnetic properties make it suitable for electrical enclosures and shielding applications, where both formability and conductivity are essential. This multi-faceted utility explains why industries ranging from aerospace to consumer goods continue to rely on low carbon steel sheets as a foundational material for innovation and production efficiency.

Comments

Post a Comment